Views: 15 Author: Site Editor Publish Time: 2023-04-25 Origin: Site

Cross needle roller linear guides are available in two highly compact designs:N/O and M/V.These types of linear guides are used for high-load applications with limited stroke.They support and guide high loads and high torques with extremely high precision.Non-recirculating bearing design can achieve super smooth linear motion.

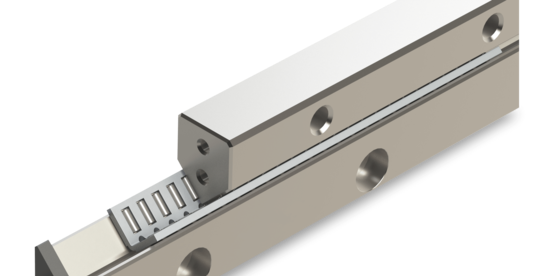

Cross needle Roller linear guides

A set of cross roller guides includes:four special V-shaped guides after special heat treatment precision grinding machining,two cross roller cage by precision roller directly combined with each other.Cross roller guide is used in combination with cross roller cage and 90°V grooved rolling surface on dedicated track.The two rows of roller guides are assembled in parallel so that they can bear loads in all directions perpendicular to the shaft.Because preloading can be simply applied,so high rigidity and light movement can be obtained without clearance.

Cross roller guides

Less space is required due to the compact structure of the roller.The contact length between the needle and the guide rail is long.Since the length of a needle roller is at least 2.4 times its diameter,their contact area is greater than that of a cylindrical roller,with a diameter to length ratio of less than 1.The diameter of the needle is smaller than that of a cylindrical roller.As a result,more needle rollers can be mounted in cages..As a result,needle roller linear guides can carry higher loads as ball and cross-roller guides with similar dimensions.

Since less space is required for the needles,the cage requires more needle rollers to distribute the load.Another major difference between cylindrical rollers and needle rollers is the smaller diameter of the needle rollers:the number of rows in the cage can be doubled,resulting in a greater contact area.Smaller rolling diameter will also increase the stiffness of linear bearings.The smaller the load per needle roller, the smaller the deformation,so rigidity may be about 50% higher than a cross roller guide RSDE of equal cage length.

All components are of the highest quality grade,with extremely high accuracy.Needle roller cages help reduce friction resistance,which is slightly higher than ball and cross roller linear bearings.

Click to select ALM high quality cross roller guide for your application: