Views: 3 Author: Site Editor Publish Time: 2023-02-17 Origin: Site

When choosing a linear system,the first application parameters that come to mind are likely to be travel,load and speed.In addition,detailed information on load placement,move profiles and duty cycles are needed to accurately calculate bearing life,which are typical criteria for evaluating a linear system.But there are other performance criteria that deserve equal consideration.Here are five factors that are often overlooked.

●Deflection

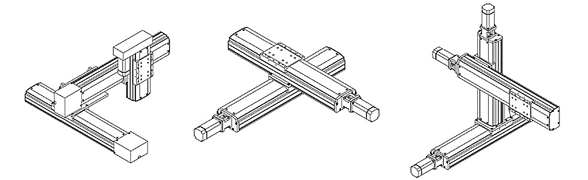

In gantry and Cartesian applications,only the base(usually "X")horizontal axis(or axes)are fully supported.In a gantry configuration,the Y axis(or axes) will be mounted only at the end,with a long overhead length between mounting points.Similarly,for a Cartesian configuration,the auxiliary horizontal axis(usually"Y")will be mounted at one end only,with most axes unsupported.

In Cartesian configurations,only the base (“X”) axis is fully supported.

Deflection of overhead actuators can lead to binding and premature wear.In many cases,however,it is relatively simple to model the actuator as a beam and the load as a point or uniform load in order to perform beam deflection calculations.The results of the predicted deflection can then be checked against the maximum allowable deflection specified by the manufacturer.

●Accuracy and repeatability

In general,if the system requires high accuracy or repeatability,ball screw or linear motor drive systems would be preferred.If the required accuracy is relatively low,belt or pneumatic actuators may be considered suitable solutions.However,these generalizations may lead to poor system performance or unnecessarily expensive systems.

●Environment

Dirt,dust,debris and liquids are all contaminants that can negatively affect the performance of a linear system.To prevent these,use a system with a robust seal or sealing mechanism,such as a linear actuator with a positive retained cover.The system can also be mounted sideways or upside down to prevent the ingress of contaminants,but remember that the orientation of the actuator affects the loads and forces on the guide and drive mechanisms.

Food and beverage applications often require washdown with corrosive chemicals.

An environmental factor that is often overlooked is temperature,The expansion and contraction of different materials can be a problem when the actuator is used in areas where the temperature changes significantly due to environmental conditions or due to the process being performed.For example,the coefficient of thermal expansion of aluminum is almost twice that of steel.As a result,actuators with aluminum bases or housings and steel guides may experience binding or unwanted stress when used in environments with high temperature variations.

●Mounting options

Linear actuators are typically mounted via clips on the side of the actuator,holes in the bottom of the housing,or slots in the housing.Mounting techniques not only affect the space required for the actuator,but may also affect deflection.In high precision gantry or Cartesian systems,actuators can be fixed and clamped to ensure parallelism and perpendicularity between axes.Mounting options can also affect the ease of maintenance.Systems that are easy to mount and un-mount will be easier to repair or replace,and can reduce unnecessary downtime.

●Maintenance

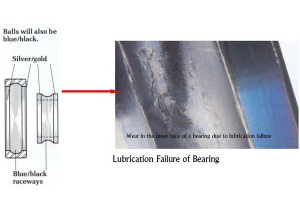

Most actuators require basic lubrication maintenance,i.e.,grease or oil for the components in metal-to-metal contact.The easiest way to lubricate an actuator is through one or more central ports that provide lubrication for all necessary components.However,some designs make central lubrication impossible.Another method is to lubricate each component directly,but the lubrication fittings must be easily accessible.Otherwise,the user may forgo proper lubrication because it is too much trouble.

Insufficient lubrication is the number one cause of bearing failure.

Another factor to consider is the location of the lubrication access on the actuator.For example,if the lubrication port is located on the side of the actuator,but other components block access,another method of lubrication or another mounting arrangement will need to be found.

Click to select ALM high quality linear motion components for your application:

Linear Module, Ball Screw, Lead Screw- ALM (autolinearmotion.com)