Views: 24 Author: Site Editor Publish Time: 2024-03-19 Origin: Site

Whether to process your lead screw shaft ends depend on your application specific needs and precision level and required durability.Most Lead screws need end machining,reasons are as following:

(1)Ensure proper fit and alignment: End machining make lead screws fit properly into the mating component,such as coupling or bearing.This can avoid misalignment and ensures lead screws and lead nuts operate smoothly.

(2)Create a mounting surface: End machining allows for the creation of a flat and smooth mounting surface for attaching the lead screw to other components or CNC machining parts.

(3)Easy to assemble: Shaft end machining can be with keyways,threads,or flats that make it easier to assemble the lead screw into a linear motion system or CNC machine.

(4)Improve performance: End machining can improve lead screw accuracy,durability and performance.

In order to simplify lead screw design,as lead screw manufacturer,ALM proposed some standard lead screw shaft end sizes, you can refer to it for your design. It will save your time and cost to choose standard lead screw shaft ends.

ALM produces both standard and custom shaft end machining,and usually we produce lead screw and nut according to your drawings.Some popular types for lead screw end machining include milling keyway,milling flat,milling circlip,Milling Hex Socked and so on.Our lead screw can meet all your challenge requirements.

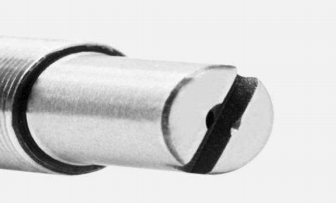

Milling Circlip

Processing Thread

Milling Keyway

Milling Slotted Drives

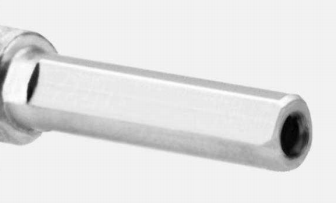

Milling Hex Socket

Milling Flat

In conclusion,If your application requires precise positioning or high load capacity,end machining may be necessary to ensure optimal performance.Additionally,end machining can help prevent damage to the lead screw during installation or operation.It is recommended to consult with a professional lead screw manufacturer to determine the best approach for your specific situation.

Contact us to get a quote! E-mail: sales@autolinearmotion.com

Lead Screws from China, Lead Screws Manufacturer & Supplier - Lead screw ball screw linear guide manufacturer China (autolinearmotion.com)