Views: 31 Author: Site Editor Publish Time: 2023-04-14 Origin: Site

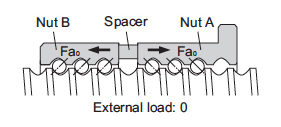

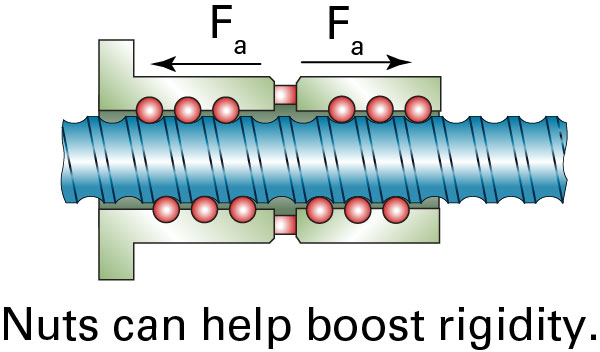

The stiffness of the ball screw depends not only on the ball screw shaft and ballnut,but also on the thrust bearing and the ballnut and bearing housing.The default way to increase the stiffness of the ball screw is to increase the preload of the ballnut.However,the ballnut is one of the most rigid parts of the ball screw assembly,so increasing the stiffness of the ballnut has little effect on the rigidity of the overall system(except for upgrading from a ballnut with no preload to a ball nut with preload).In addition,higher preload leads to higher frictional torque,which means more heat is generated and more torque is required to drive the ball screw.Double ballnuts are more rigid than single ballnuts,but have little impact because the ballnut is already so rigid relative to other components.

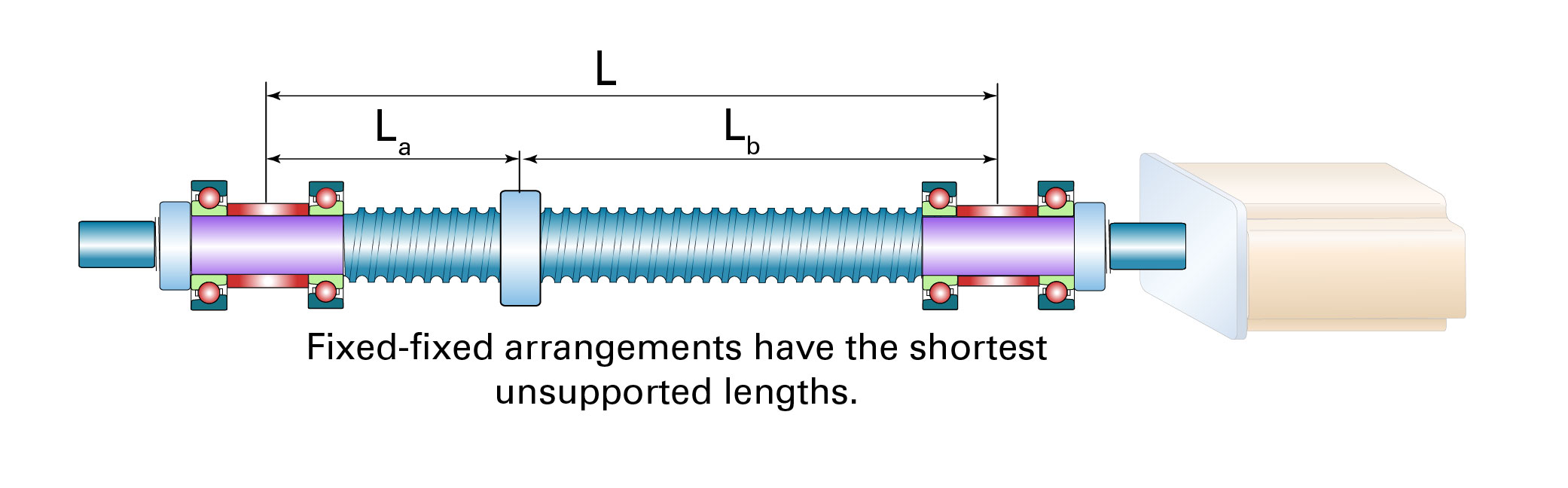

The limiting factor in the rigidity of the ball screw assembly is usually the ball screw shaft.The stiffness of a ball screw shaft depends on its elastic modulus,diameter(which determines its cross-sectional area),and overhead length.The elastic modulus of a ball screw depends on the material(usually steel),and its diameter depends mainly on the thrust and speed required.The overhead length of the ball screw shaft is determined by the stroke and end bearing configuration.

The rigidity of double ballnuts is higher than that of single nuts,but the overall influence on the rigidity of ball screw system is relatively small.Although ball screw material and diameter are usually determined by application,the end bearing configuration(and its effect on overhead length)is selected based on factors such as speed,buckling load,and stiffness.

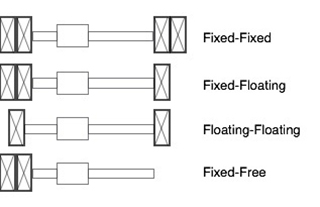

There are four common end bearing combinations for ball screw assemblies.From most rigid to least rigid,they are:fixed-fixed,fixed-floating,floating-floating,and fixed-free.

The fixed end uses angular contact thrust bearings,which are used to support radial and axial loads,while the floating end uses simple radial bearings,which do not support axial loads.

The free end has no bearing support.Compared with the least rigid unfixed bearing configuration,the use of the most rigid bearing configuration - fixed - fixed - increases the rigidity of the ball screw shaft by four times.This is due to two design advantages.

Fixed-fixed end bearing configurations provide the highest rigidity,while non-fixed bearing configurations are the least rigid configurations.

First,angular thrust bearings are used at both ends,allowing force to be transferred through ball screws on either side of the ballnut.Furthermore,for thrust bearings at both ends,the maximum distance between the ballnut and either fixed bearing occurs when the ball nut is in the middle of the stroke,meaning that the overhead length is half the length of the ball screw.

In fixed-fixed-end bearing configurations,the maximum overhead length is 1/2 of screw balllength (La=Lb).

Another effective way to increase the stiffness of the ball screw is to change the way the assembly operates:hold the ball screw still and rotate the ballnut.In a rotary ballnut design,support bearings are not required at the end of the screw shaft since the screw itself does not rotate.Instead,the ballnut is supported by a large angular contact thrust bearing.The ball screw shaft is rigidly mounted at both ends,allowing torsional torque to be transferred to the mounting seat at both ends of the ball screw.Although the rotary ballnut assembly is very rigid,its structure may present size and interference problems for applications where standard rotary ball screw assemblies are considered in the design.

Driving the ballnut(not the ball screw shaft)results in a very strong ball screw assembly.

Click to select ALM high quality ball screws for your application: